Benefit:

☑️Yield increased by 3 to 5 times

☑️Lowest noise levels

☑️Minimal maintenance

☑️No daily lubrication required

☑️Minimal wear part consumption

☑️Long lifespan of components and materials

☑️Reduced fuel consumption

☑️Lower emissions

☑️Underwater operations

☑️Simple operation

☑️Improved operator comfort

The YONDA ripper's closed energy chamber can not be influenced or damaged from the outside by dust, water, dirt or what so ever.

This means that it can work without any problem in the most severe conditions in tunnels, foundations, muddy and wet places.

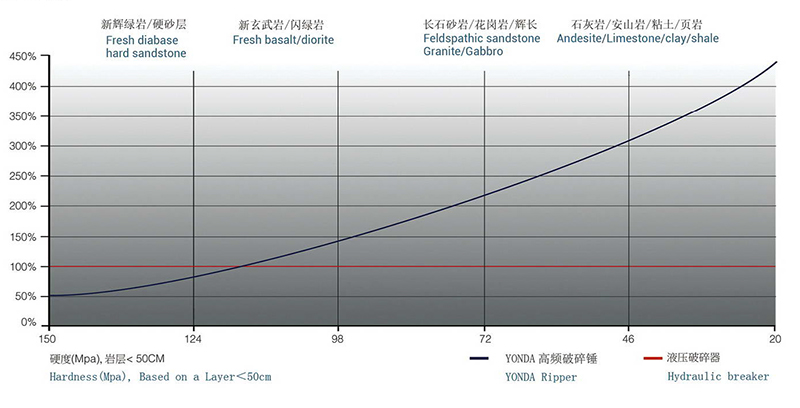

Productivity Comparison Chart:

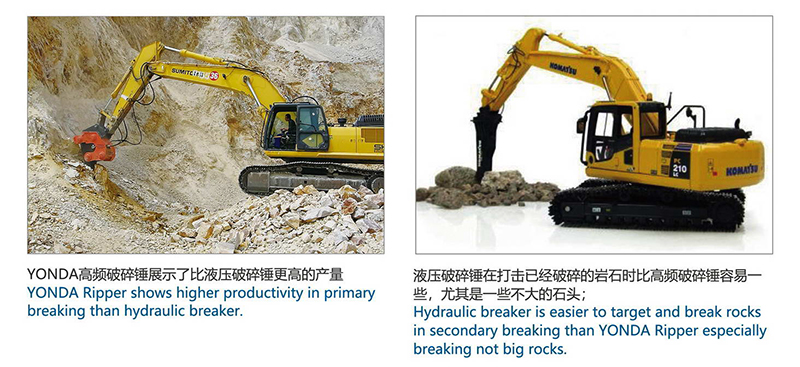

The Yonda ripper widely exceeds the hydraulic breaker production in 80% of job applications.

In up to 70% of the job applications, a 2 to 5 times higher production can be achieved.

Noise Comparison:

The noies level is nearly same as excavating with bucket as YONDA Ripper does not equip striking mechanism inside body.

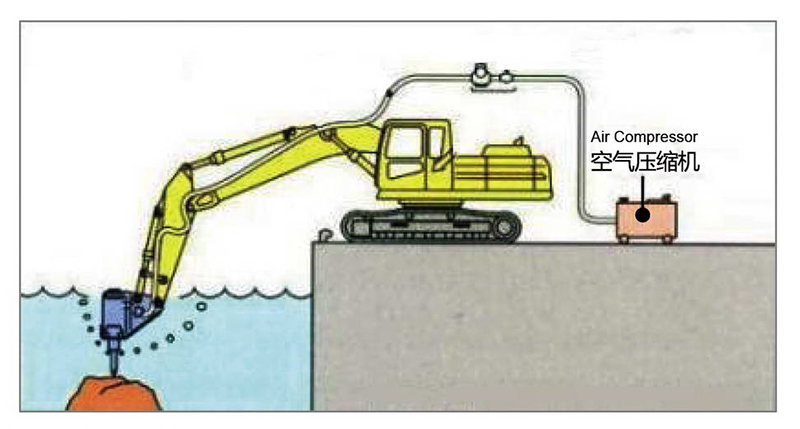

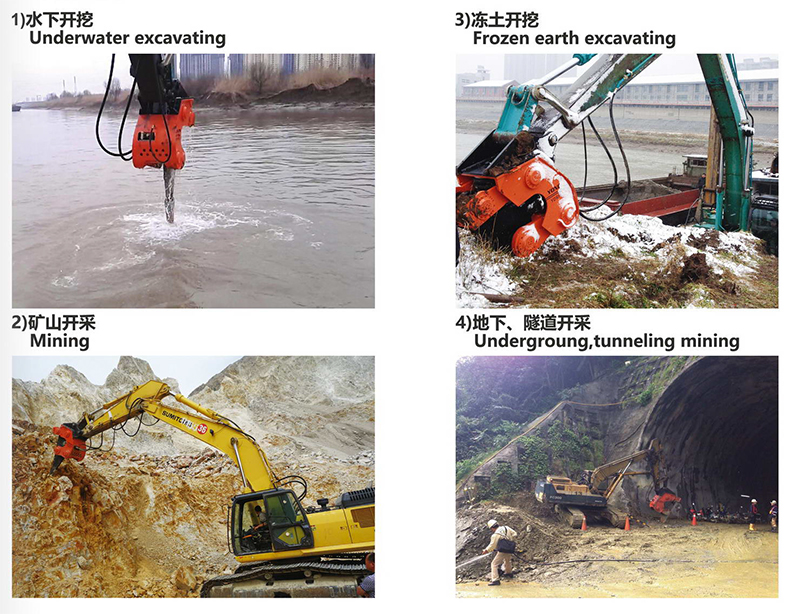

Underwater Operation:

Because the internal components of the high-frequency hammer are completely sealed, it will not be damaged by water, dust, or dirt.

This means that it can work in harsh environments such as tunnels, mines, ports, etc. without being restricted by the environment.

When working underwater with high-frequency hammers, complex preparations are not required, and maintenance and repair costs can usually be saved based on the local working environment.

Without special modification, the YONDA high-frequency hammer is fully suitable for underwater operation without any performance degradation.

The hydraulic crushing hammer requires special modification when working underwater.

If the modification is not complete, it is easy to cause damage to the excavator.

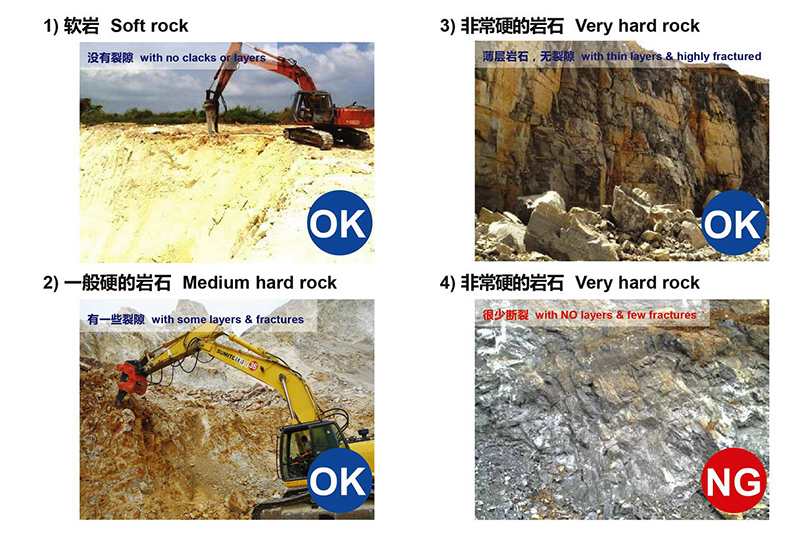

Suitable Rock Conditions For High-Frequency Hammers:

Target Customers:

We believe that for customers with the following needs, the high-frequency breaker will be an

excellent choice.

1. Customers looking to increase production in quarries who already have another machine equipped with a hydraulic breaker for secondary crushing.

2. Customers dissatisfied with the production output of buckets in hard soil layers and wishing to improve it.

3. Customers looking to save on maintenance and warranty costs.

4. Customers seeking a machine that can substitute for blasting in quarries where it is not permitted while maintaining high production levels.

5. Customers currently using hydraulic breakers for underwater, port, canal, and tunnel construction.

6. Customers particularly focused on trenching projects.

7. Customers involved in concrete structure demolition, among others.

Application Case:

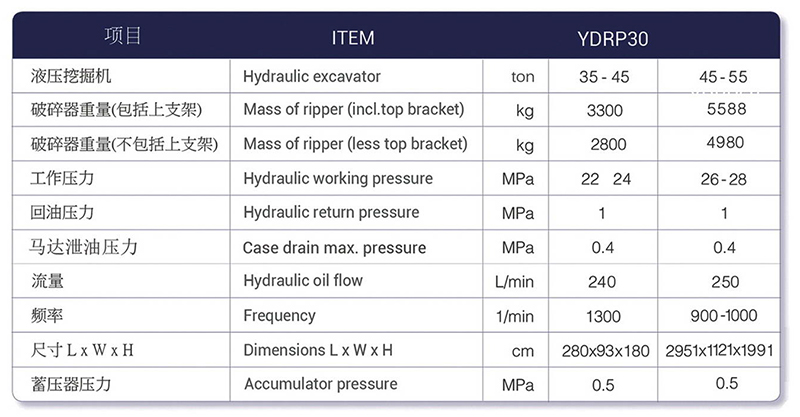

Parameter