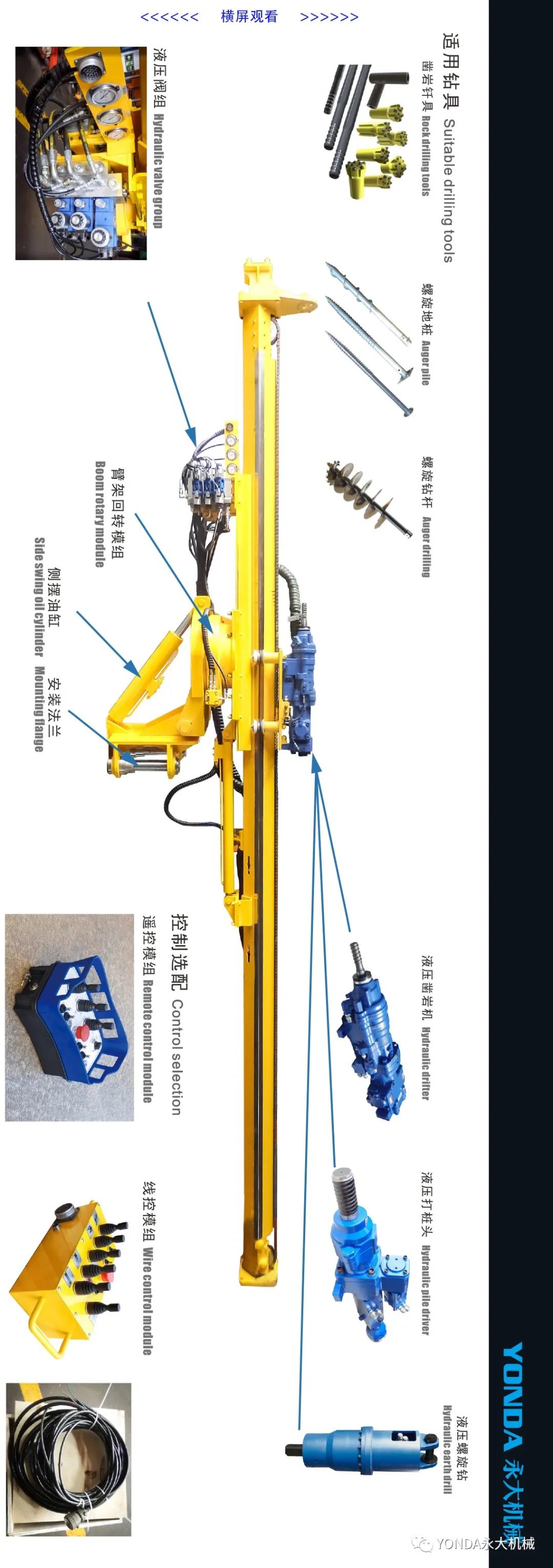

The YONDA excavation to drilling system can be conveniently and quickly installed on the front end of various excavation loaders, wheel excavators, tracked excavators, etc.

It is equipped with a specially designed integrated hydraulic control system, which can perfectly connect the original hydraulic pipeline of the crushing hammer with the original hydraulic system of the excavator, without affecting its original functions, and is easy to install and maintain.

The excavator-mounted drilling series is divided into three categories: piling, rock drilling, and auger drilling, allowing for flexible selection based on requirements. Wired or wireless remote control options are available.

System Components:

Auger Drilling Series:

The auger drill is a construction foundation device that is easy to operate, flexible, and highly efficient. It is suitable for various engineering fields, performing quick drilling and hole formation on all types of soil layers. It is an ideal drilling equipment for tasks such as landscaping, tree planting, well drilling, foundation piling, helical piling, solar panel installation, photovoltaic piling, and column installation.

Rock Drilling Series:

The YONDA rock drilling series offers a selection of YONDA hydraulic rock drills with various power levels to meet drilling requirements. Easy to install and highly integrated, it can replace common open-air and tunnel drill rigs, making it suitable for applications such as open-pit blasting, tunnel excavation support, and anchor rod support. Compared to traditional drill rigs, utilizing existing excavators reduces costs, enhances maneuverability, expands the work area, and provides flexible operation, offering an exceptional cost-performance ratio.

Piling Series:

The YONDA piling series consists of the YDH2M hydraulic impact piling hammer, drilling arm system, and hydraulic control system, which can be mounted on the front end of various excavators as attachments. It serves as an alternative to most guardrail piling machines, road piling machines, and photovoltaic piling machines.

By leveraging the excavator's powerful off-road capabilities and flexible arm mechanisms, this system adapts well to diverse terrains, extends the working radius, and improves efficiency. Additionally, by utilizing the user's existing excavator equipment, it significantly reduces equipment investment costs, generating greater profit for the user.

Company News

Company News